The green production concept emphasizes minimizing the impact on the environment and achieving efficient and circular utilization of resources throughout the entire life cycle of product design, production, use and waste disposal. In the field of auto parts die casting, this concept prompts companies to adopt more environmentally friendly production processes and materials, reduce the generation of solid waste, and strengthen the recycling and reuse of solid waste.

Classification collection and scientific treatment

There are many types of solid waste generated during the die casting process, including scrap metal, scrap sand, scrap slag, etc. Enterprises need to establish a scientific classification collection system to separate different types of solid waste. For scrap metal, it can be recycled through smelting, regeneration and other processes; for scrap sand, scrap, etc., high-temperature melting, anaerobic degradation, thermal cracking and other technologies can be used for harmless treatment and resource utilization.

Application of high-temperature melting technology

High-temperature melting technology is an effective means of solid waste treatment, especially for treating solid waste containing heavy metals and toxic and hazardous substances. Through high-temperature melting, harmful substances in solid waste can be decomposed and purified, while achieving solid waste reduction and resource utilization.

Anaerobic degradation and energy recovery

Anaerobic degradation technology uses the decomposition of microorganisms under anaerobic conditions to convert organic matter in solid waste into clean energy such as biogas. This technology not only achieves harmless treatment of solid waste, but also achieves energy recovery and utilization.

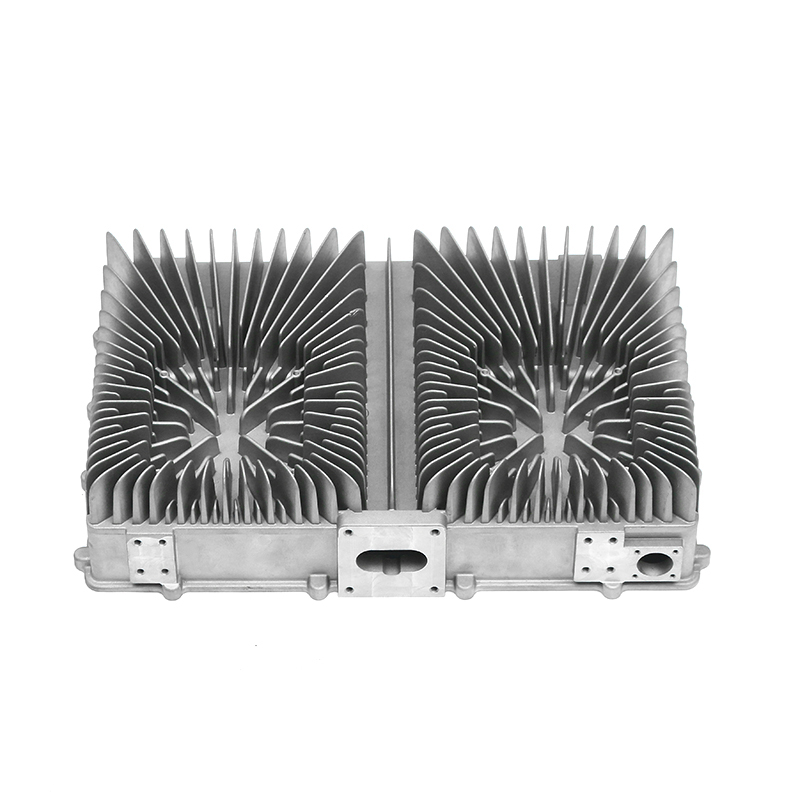

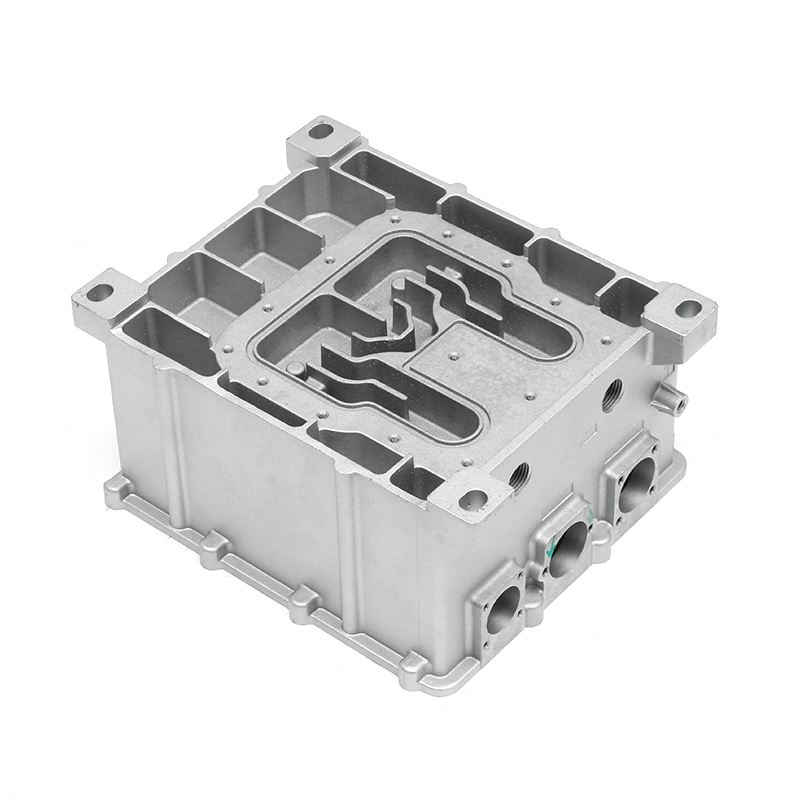

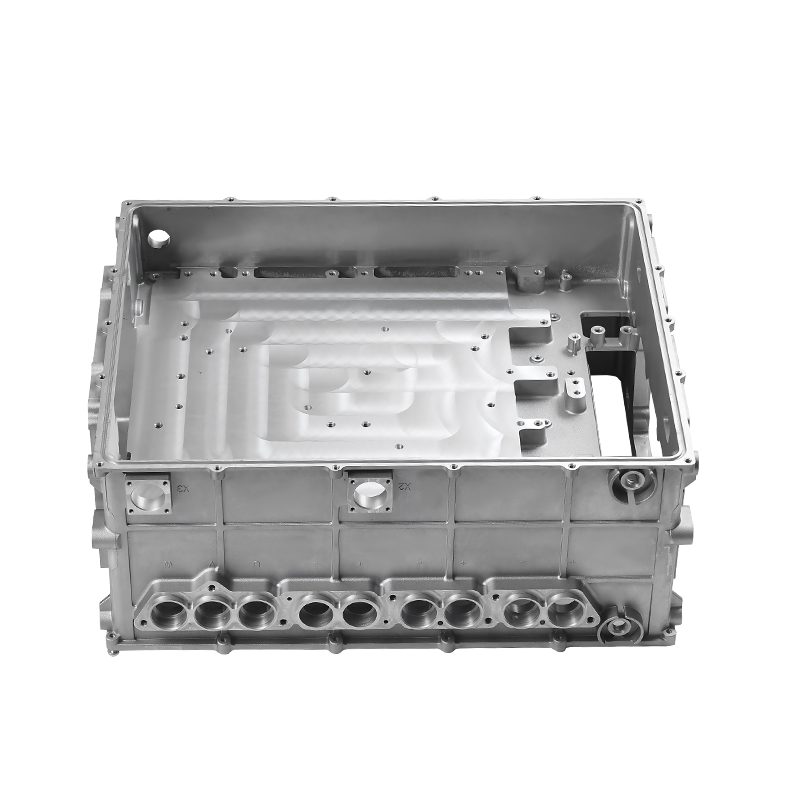

Recommended Products

Products provided by famous enterprises are deeply trusted by users.