The manufacturing process of new energy vehicle mold die castings usually includes the following main steps:

Mold design: Design the mold according to the design requirements and specifications of the product. This includes determining the structure, size, cooling system, pouring system, etc. of the mold. Mold design needs to take into account the shape, material properties and production process requirements of the product.

Mold making preparation: Before making the mold, the required materials and tools need to be prepared. High-strength metal materials, such as steel or aluminum, are often used to manufacture the core cavity and other components of the mold. At the same time, prepare the machine tools, cutting tools and measuring tools required for processing.

Mold processing: Mold processing is the core link in manufacturing molds. The processing process usually includes the following steps:

CNC machining: Use CNC machine tools to process the mold core cavity to achieve the shape and size required by the design.

Electrical discharge machining: Use electric spark discharge technology to process the details of the mold, such as slotting, hole processing, etc.

Wire cutting: Use a wire cutting machine to cut mold parts to obtain the desired shape and size.

Milling and drilling: Use milling machines and drilling machines for face milling and hole processing of molds, etc.

Assembly and debugging: After the mold processing is completed, the mold is assembled and debugged. This includes assembling the various parts of the mold and ensuring that they are structurally and functionally functioning properly. Conduct debugging and testing of molds to verify their performance and accuracy.

Polishing and surface treatment: After completing the assembly of the mold, polishing and surface treatment are performed. Polishing can improve the surface finish of the mold, and surface treatment can improve the wear resistance and corrosion resistance of the mold.

Mold trial production and adjustment: Carry out trial production of molds, use molds for small batch production, and conduct product quality inspection. Based on the trial production results, necessary adjustments and optimizations are made to ensure that the quality and performance of mold manufacturing meet the requirements.

Mold maintenance and upkeep: After the mold is manufactured, regular maintenance and upkeep is required. This includes cleaning the mold, repairing damaged parts, lubricating mold parts, etc. to extend the life of the mold and maintain its performance.

The above is the general manufacturing process flow of new energy vehicle mold die castings. The actual manufacturing process may vary depending on the specific product and manufacturer, but these steps provide a basic overview showing the main processes involved in mold die casting manufacturing.

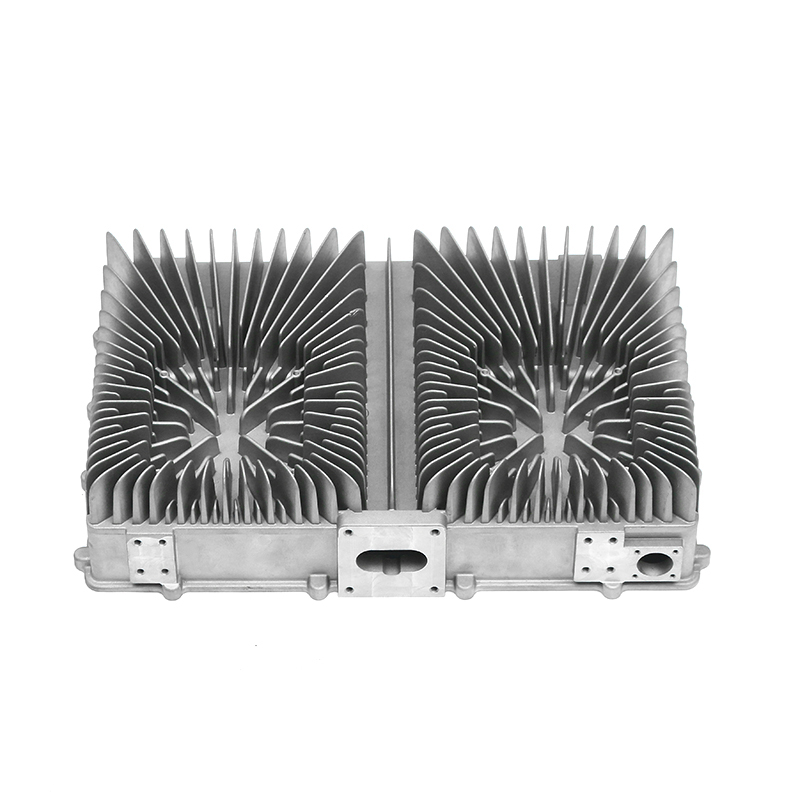

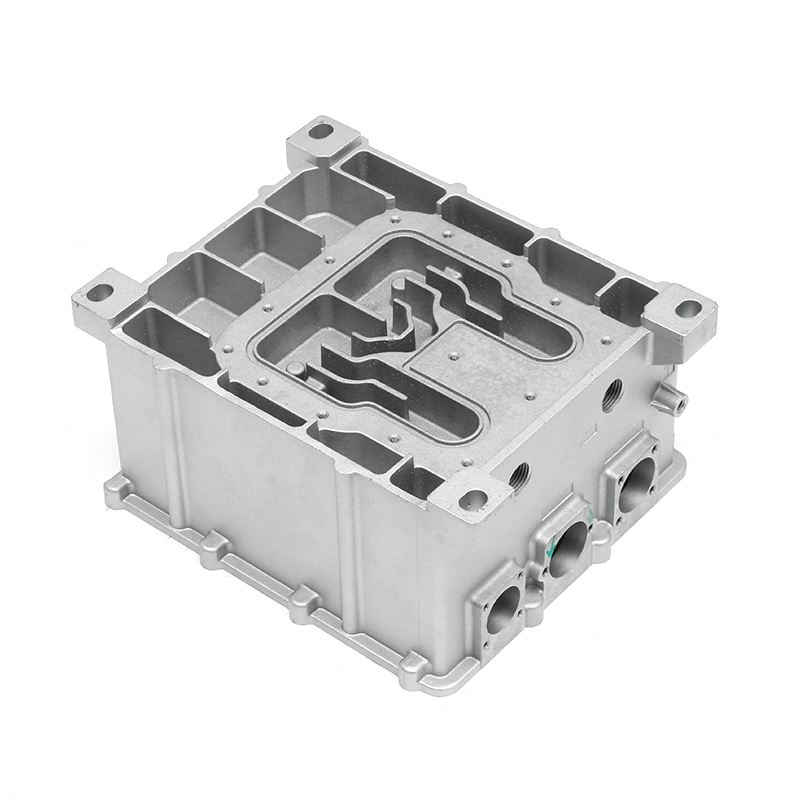

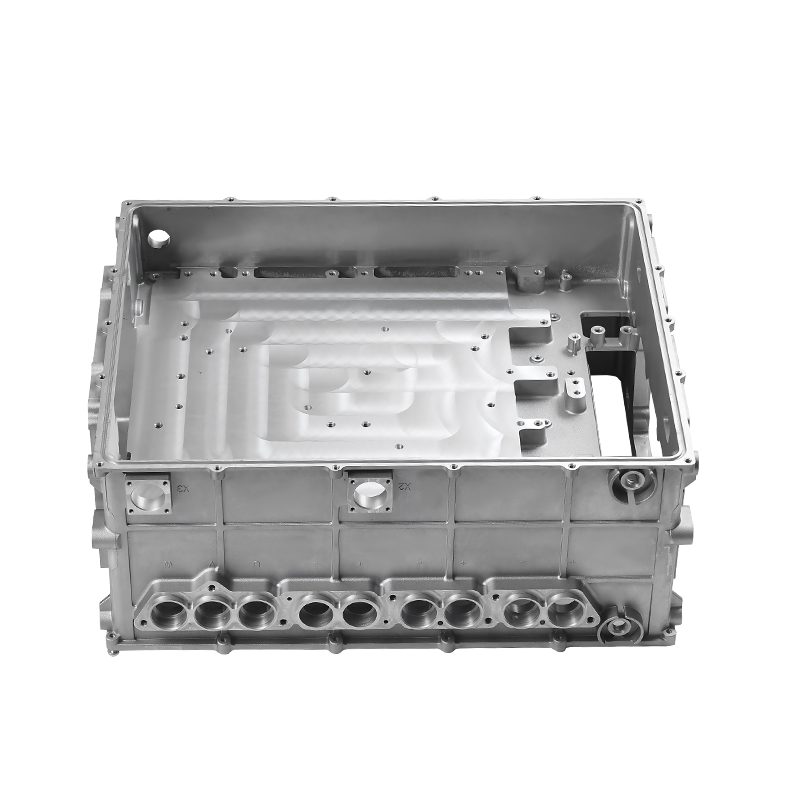

Recommended Products

Products provided by famous enterprises are deeply trusted by users.