The manufacturing trend of new energy vehicle molds is mainly affected by technological progress, market demand and sustainable development. The following are some manufacturing trends for new energy vehicle molds:

Rapid manufacturing technology: As competition in the new energy vehicle market intensifies, manufacturers need to develop and manufacture molds more quickly. Rapid manufacturing technologies, such as rapid prototyping (such as 3D printing), rapid processing and rapid assembly, can significantly shorten the mold manufacturing cycle and improve production efficiency.

Intelligent manufacturing and automation: Intelligent manufacturing and automation technology are increasingly used in new energy vehicle mold manufacturing. Intelligent mold design software, intelligent processing equipment and robotic systems can improve work efficiency, reduce production costs and ensure consistent product quality.

High precision and complex structure: The design of new energy vehicles tends to be more energy efficient and lightweight, so mold manufacturing needs to meet higher precision and complex structure requirements. The application of high-precision machining equipment, advanced measurement technology and mold design optimization tools can meet these requirements.

Materials and coating technology: New energy vehicle molds need to have high strength, high hardness and wear resistance. Therefore, the development and application of new mold materials and surface coating technologies are becoming increasingly important. For example, the use of high-performance alloy materials, ceramic materials and advanced surface coatings can improve the life and durability of molds.

Green manufacturing and sustainable development: New energy vehicle mold manufacturing is also paying more and more attention to green manufacturing and sustainable development. This includes efforts to reduce energy consumption, optimize material utilization, and reduce waste and pollutant emissions. The use of renewable materials and recycling of waste are also part of the manufacturing trend.

Cooperation and innovation: New energy vehicle mold manufacturing involves multiple fields and expertise, so cooperation and innovation are becoming increasingly important. Knowledge sharing and technical collaboration among partners can accelerate the development of mold manufacturing and promote technological innovation and advancement.

These trends reflect the development direction of the new energy vehicle mold manufacturing industry to adapt to the changing and developing market needs. As technology advances and the industry continues to evolve, new manufacturing trends will continue to emerge.

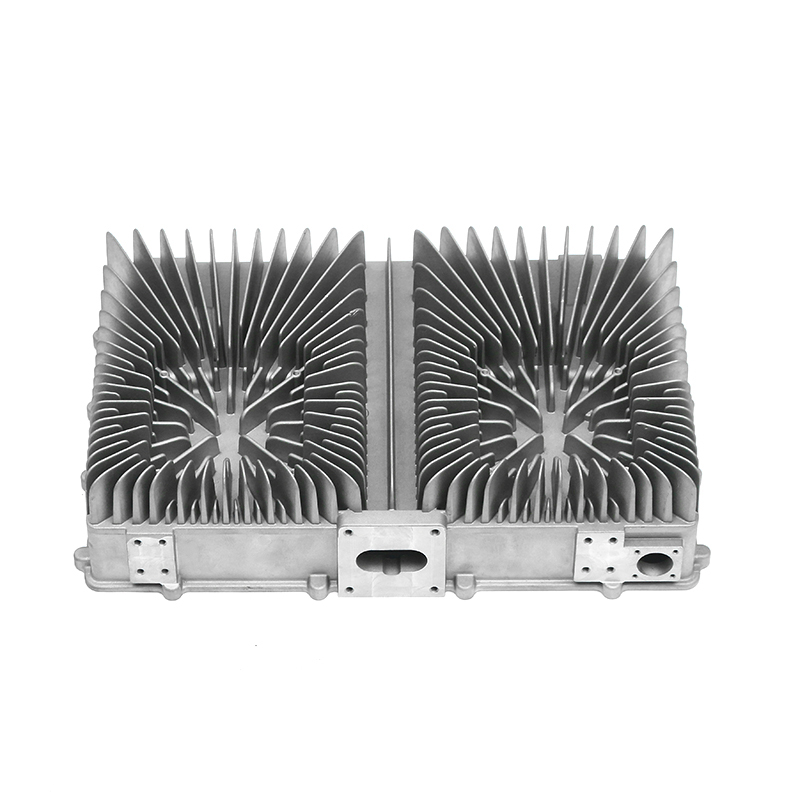

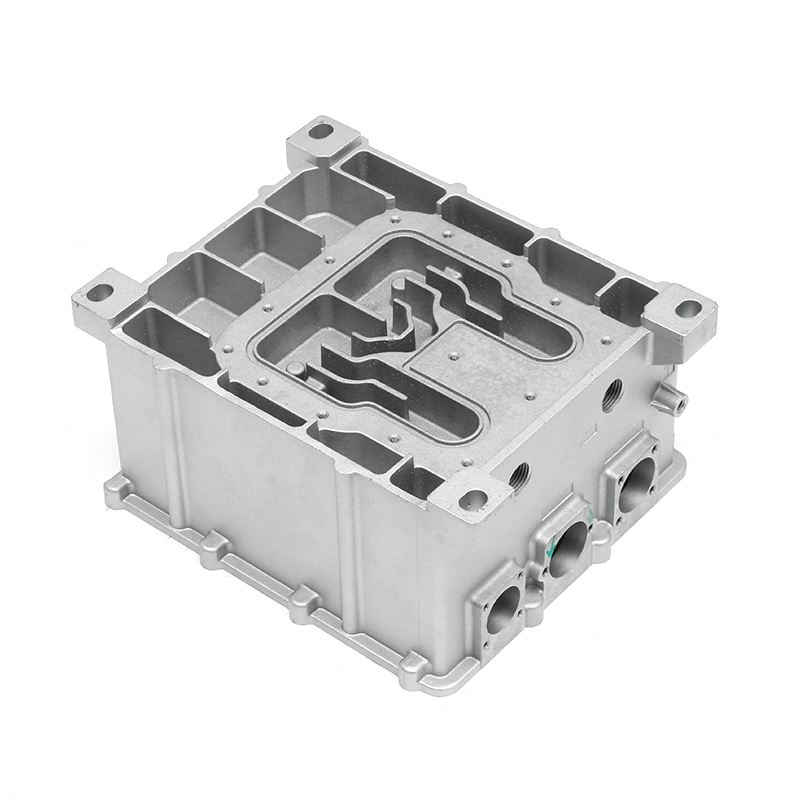

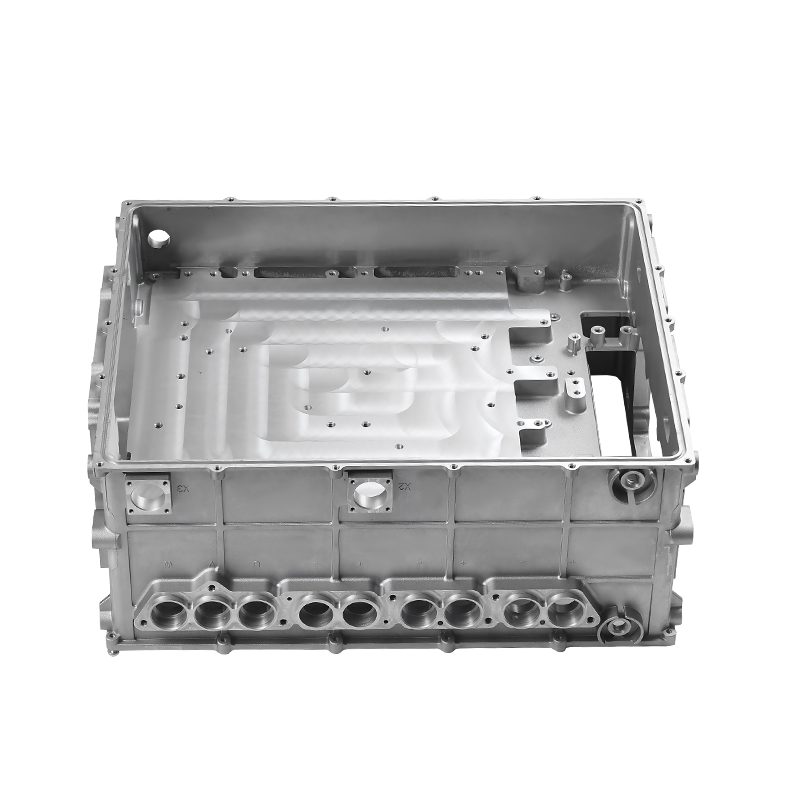

Recommended Products

Products provided by famous enterprises are deeply trusted by users.