The life and maintenance of new energy motor housing molds are crucial to the stability and production efficiency of the molds. The following are some important considerations regarding the life and maintenance of new energy motor housing molds:

Material selection: Choose mold materials with high quality, good wear resistance and corrosion resistance, such as tool steel, hot tool steel or carbide, etc. Suitable materials can improve the hardness and durability of the mold and extend its service life.

Mold design and manufacturing quality: Carry out reasonable mold design to ensure that the mold structure is strong, rigid, and dimensionally accurate. At the same time, the mold manufacturing process is strictly controlled to ensure the quality and accuracy of the mold to reduce the loss and failure of the mold during use.

Usage environment and process control: Keep the mold working in an appropriate usage environment and avoid the influence of excessive temperature, humidity or corrosive media. At the same time, the process parameters during the use of the mold are strictly controlled to avoid damage to the mold caused by overload operation or poor processing conditions.

Mold care and maintenance: Regular mold maintenance and upkeep is the key to extending the life of the mold. This includes cleaning the mold surface, lubrication of mold parts, regular inspection of mold wear, timely replacement of damaged or severely worn mold parts, etc. In addition, rational use of molds, proper storage and protection of molds are also important maintenance measures.

Mold Repair and Refurbishment: When molds show minor damage or wear, mold repair and refurbishment can be considered. Repairs can include local repairs, repair surface coatings, etc. to restore the functionality and service life of the mold.

Regular inspection and evaluation: Regularly check the wear degree and performance status of the mold, and promptly evaluate the service life and maintenance needs of the mold. Based on the evaluation results, make corresponding maintenance plans and measures.

Training and technical support: Provide training to mold operators to familiarize them with the correct use and maintenance of molds. At the same time, establish a good cooperative relationship with mold manufacturers and obtain necessary technical support and guidance.

In summary, through appropriate material selection, good mold design and manufacturing quality, appropriate use environment and process control, as well as regular maintenance and upkeep measures, the service life of the new energy motor housing mold can be effectively extended and improved. Production efficiency and quality.

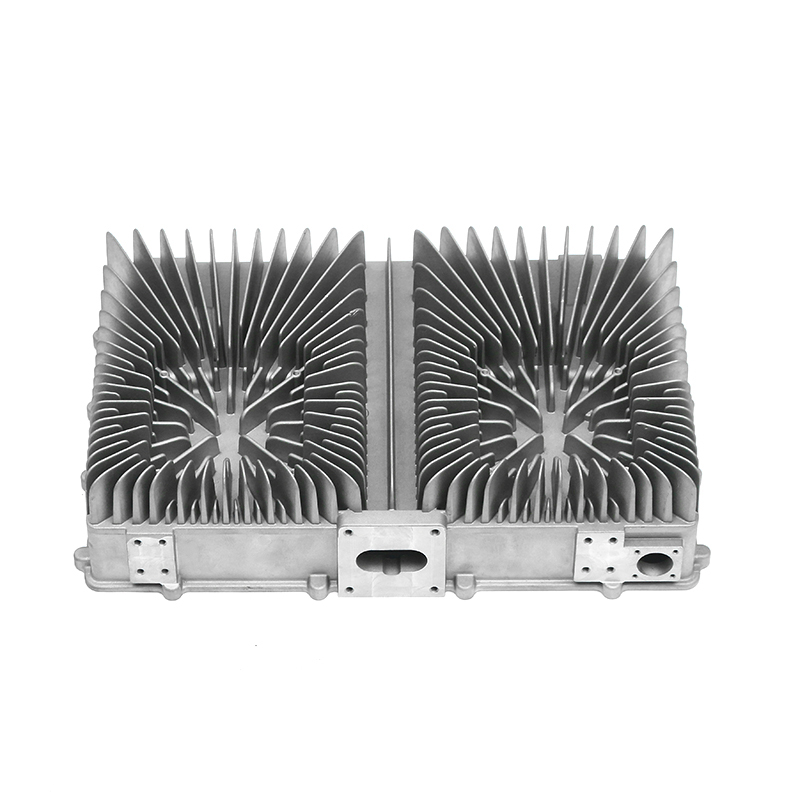

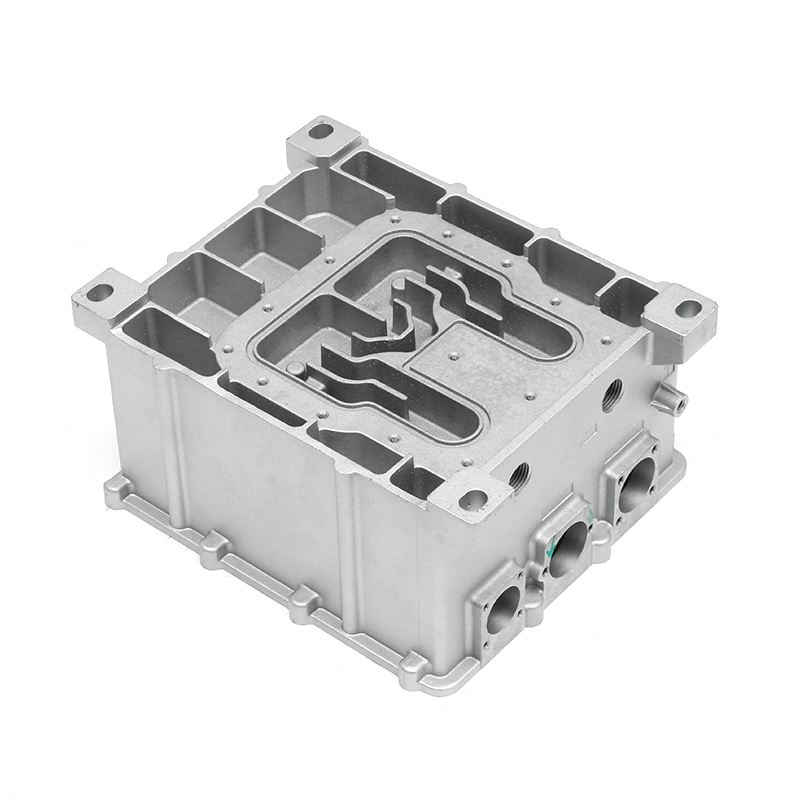

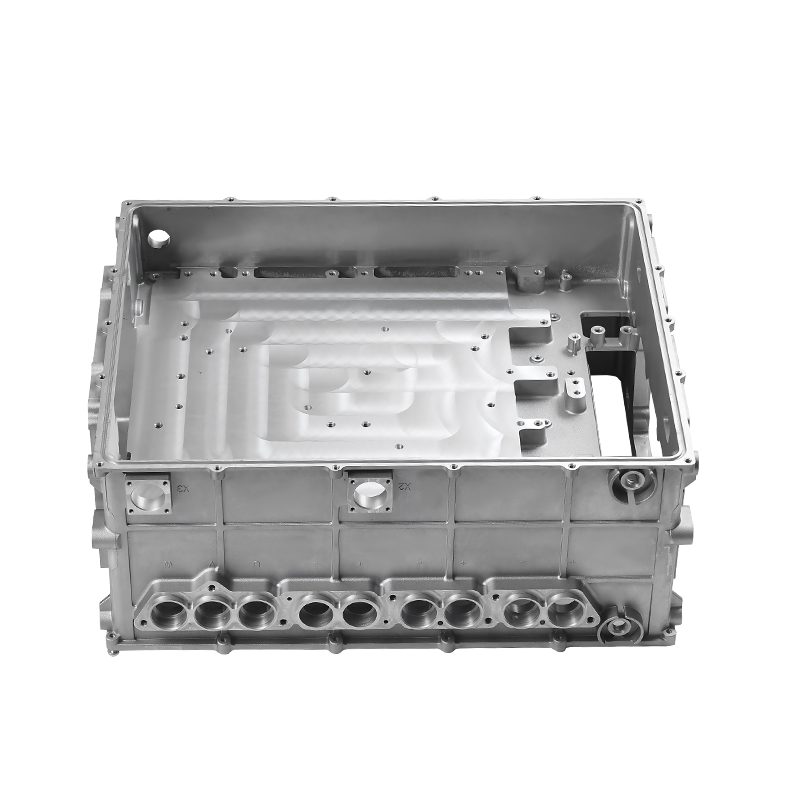

Recommended Products

Products provided by famous enterprises are deeply trusted by users.