For the application of heat-free die-cast aluminum alloys in new energy motor housing die casting, the modification of material design is a crucial link. Modification mainly improves the alloy's solidification structure, refines the grains, and eliminates or reduces harmful phases in the alloy by adding a trace amount of modifier to the alloy, thereby improving the alloy's mechanical properties, processing properties and corrosion resistance.

Selection of modifier

The selection of modifiers needs to be determined according to the specific composition and performance requirements of the alloy. Commonly used modifiers include sodium (Na), strontium (Sr), antimony (Sb), barium (Ba) and rare earth elements (such as lanthanum La, cerium Ce, neodymium Nd, etc.). These modifiers can be adsorbed on the growth front of the crystal during the solidification process of the alloy, inhibiting the excessive growth of the crystal, thereby refining the grains.

Mechanism of modification

Grain refinement: Modifiers can hinder the growth of crystals and reduce the grain size, thereby improving the strength and toughness of the alloy. Small grains mean more grain boundaries, which can hinder the expansion of cracks and improve the fracture toughness of the alloy.

Improve the structure: The modification treatment can change the phase composition and distribution in the alloy, reduce or eliminate harmful phases such as needle phases and feather phases, and make the structure more uniform and dense. This helps to improve the mechanical properties and processing properties of the alloy.

Improve performance: Through modification treatment, the mechanical properties of the alloy such as tensile strength, yield strength, and elongation can be significantly improved. At the same time, the corrosion resistance and wear resistance of the alloy can also be improved to a certain extent.

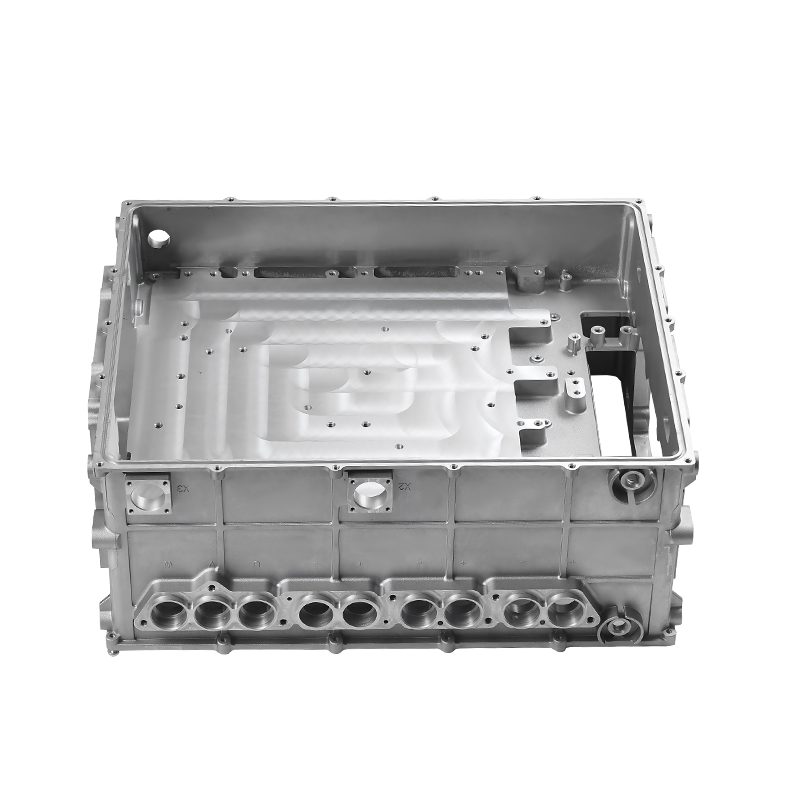

Recommended Products

Products provided by famous enterprises are deeply trusted by users.