The oil filter base plays a crucial role in ensuring the sealing and secure attachment of the oil filter during operation.

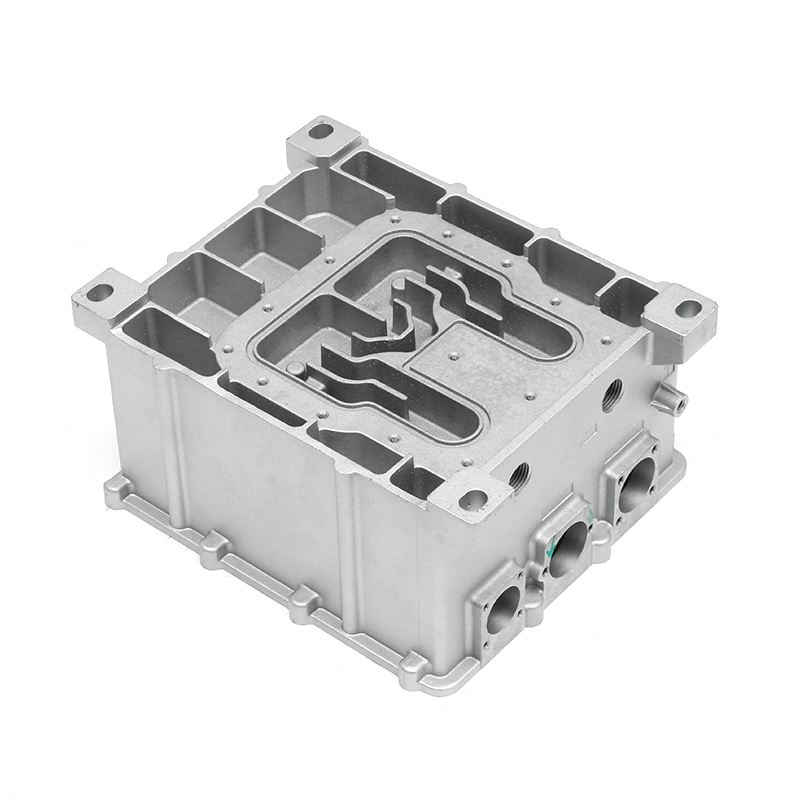

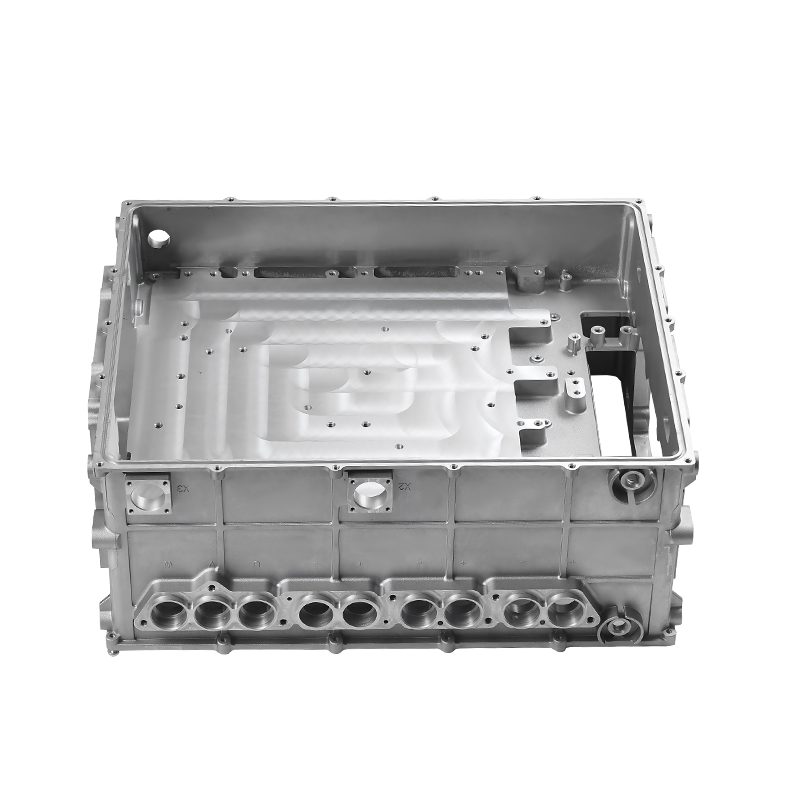

Many oil filter bases feature a threaded connection where the filter is screwed onto the base. This creates a strong, secure attachment, ensuring that the filter remains in place during operation. The threads are designed to withstand the pressures inside the engine, preventing the filter from loosening or detaching.The tight fit between the threads of the base and the filter ensures a secure connection, preventing leaks and ensuring the filter stays attached even during high vibration or engine movement.

The mounting flange on the oil filter base is often designed with a specific shape and surface texture that ensures the filter fits securely onto it. This flange ensures the filter is aligned correctly and prevents it from slipping or misaligning during operation.The flange may include grooves or recesses that help center the filter and prevent it from shifting or vibrating loose during engine operation.

Some oil filter bases have positive retention mechanisms, such as locking tabs or clips, that physically prevent the filter from coming off or shifting out of place. These mechanisms provide extra security, especially in systems with high vibration or movement.In heavy-duty machinery or automotive applications, these mechanisms are particularly important to ensure the filter stays securely attached even under demanding conditions.

The oil filter base is designed to handle the internal pressure of the oil system. As oil circulates through the engine, it generates pressure, and the oil filter must withstand this pressure without the filter detaching or leaking. The oil filter base ensures the filter remains firmly attached by maintaining a tight seal that can handle these pressures.In some cases, the oil filter base may also feature a pressure relief valve that ensures the proper pressure is maintained, preventing excessive force from dislodging the filter.

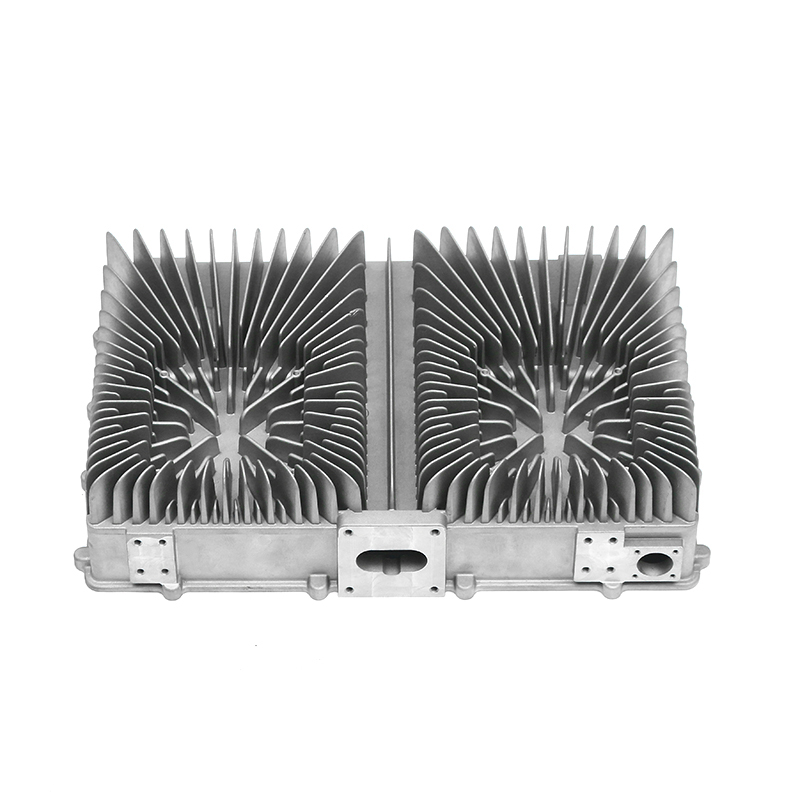

In some applications, particularly in high-performance engines or heavy machinery, the oil filter base may be designed with vibration-dampening features. These features help absorb engine vibrations, reducing the risk of loosening or detachment of the oil filter.The material used for the oil filter base may also contribute to minimizing the impact of vibrations, ensuring that the filter remains securely attached during engine operation.

The materials used to manufacture the oil filter base, such as aluminum, steel, or composite materials, are chosen for their durability and resistance to pressure, heat, and corrosion. This ensures that the base can maintain its integrity over time and during long operating periods, preventing failure that could lead to leaks or detachment of the oil filter.Some bases also incorporate anti-corrosion coatings to prevent degradation, ensuring the seal remains effective over the lifespan of the engine.

Many oil filter bases are designed to make the filter replacement process simple and secure. The base typically includes features like easy-thread connections, alignment guides, and O-ring channels, making it easier for the user to install a new filter while ensuring the proper seal and attachment.

In some systems, the oil filter base may also have a drain-back valve or anti-drainback valve that helps maintain the seal and keep oil from flowing backward into the filter when it is not in use, further ensuring secure attachment during both operation and filter change.

Recommended Products

Products provided by famous enterprises are deeply trusted by users.