New energy vehicles have extremely high requirements on the response speed of the car water pump, which is mainly due to the complexity and high-efficiency requirements of the new energy vehicle power system.

The operating characteristics of the power system of new energy vehicles, especially electric vehicles and hybrid vehicles, are significantly different from traditional fuel vehicles. Key components such as battery packs, electric motors and controllers will generate a large amount of heat during operation. If this heat cannot be dissipated in time, it will have a serious impact on vehicle performance and safety. Therefore, the water pump of new energy vehicles needs to have extremely fast response speed to ensure that it can start quickly and increase the coolant flow when the power system needs to be cooled, thereby effectively reducing the system temperature.

Dynamic adjustment and intelligent control

The water pump system of new energy vehicles is usually closely integrated with the vehicle control system (VCU) to achieve intelligent control. VCU will dynamically adjust the speed and flow of the water pump based on the real-time operating status and temperature data of the power system. This dynamic adjustment requires the water pump to have extremely high response speed so that it can be executed immediately after receiving instructions from the VCU, thereby ensuring precise control of the cooling system.

Reduce thermal shock and improve durability

A fast-response car water pump also helps reduce thermal shock to the power system. Under bad operating conditions such as fast charging or high power output, the temperature of the power system will rise sharply. If the response speed of the car water pump is not fast enough, the cooling system will not be able to respond in time, thereby increasing the thermal load and thermal stress of the power system. The water pump with fast response speed can quickly increase the coolant flow, effectively alleviate thermal shock, and improve the durability and reliability of the power system.

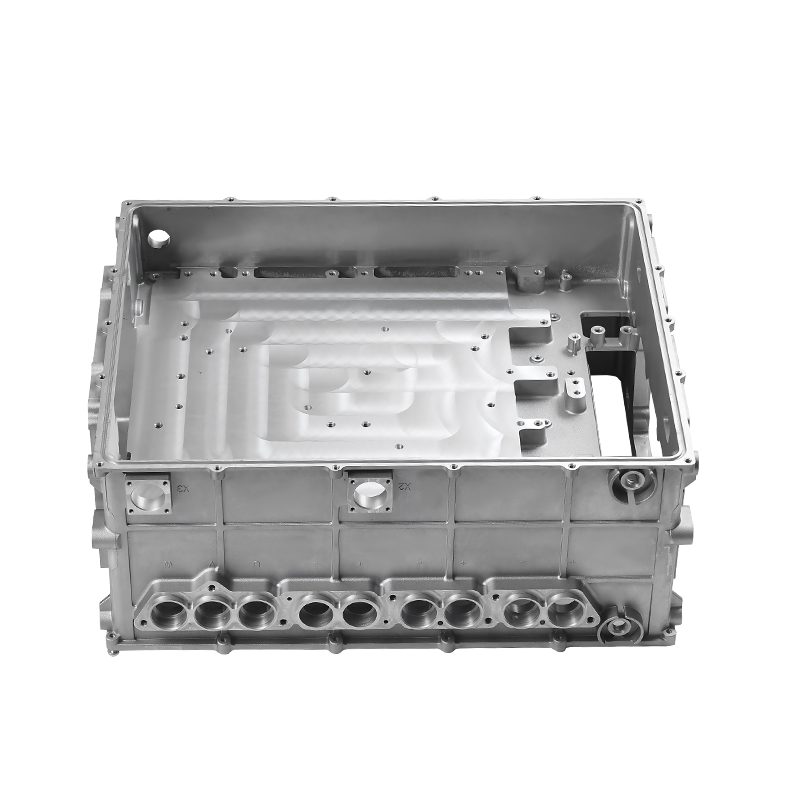

Recommended Products

Products provided by famous enterprises are deeply trusted by users.