Nano coating technology is to enhance the corrosion resistance, wear resistance and oxidation resistance of materials by coating a nano-level protective film on the surface of the substrate. The core advantage of this technology is that the coating thickness is extremely thin, but it can provide significant surface protection effect, especially for parts such as gearbox housings that require lightweight and high strength. Compared with traditional surface treatment processes such as spraying and anodizing, nano coating technology has shown several significant advantages.

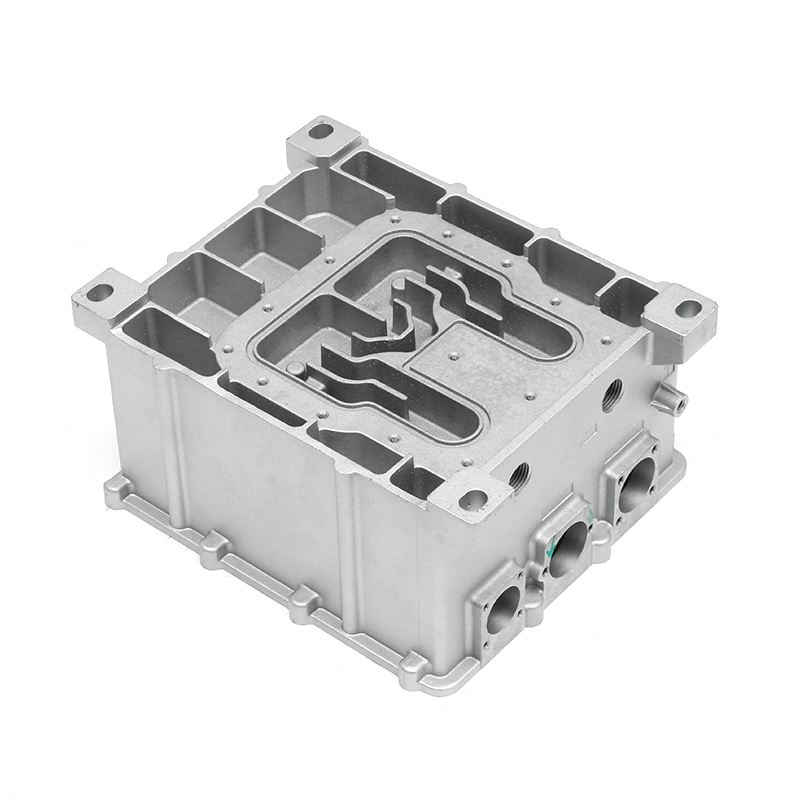

The gearbox housing is exposed to complex environments such as high humidity, salt spray, muddy water, etc. for a long time, and the surface is prone to corrosion and oxidation, especially in the high-pressure environment of new energy vehicles, where electrochemical corrosion is more likely to occur.

Nano coating technology can effectively block the penetration of moisture, oxygen and corrosive media by forming a dense protective layer on the surface of the housing, thereby greatly improving the corrosion resistance of the gearbox housing. This protective layer can remain stable during long-term use, thereby extending the service life of the gearbox housing and reducing the maintenance frequency and cost of the vehicle.

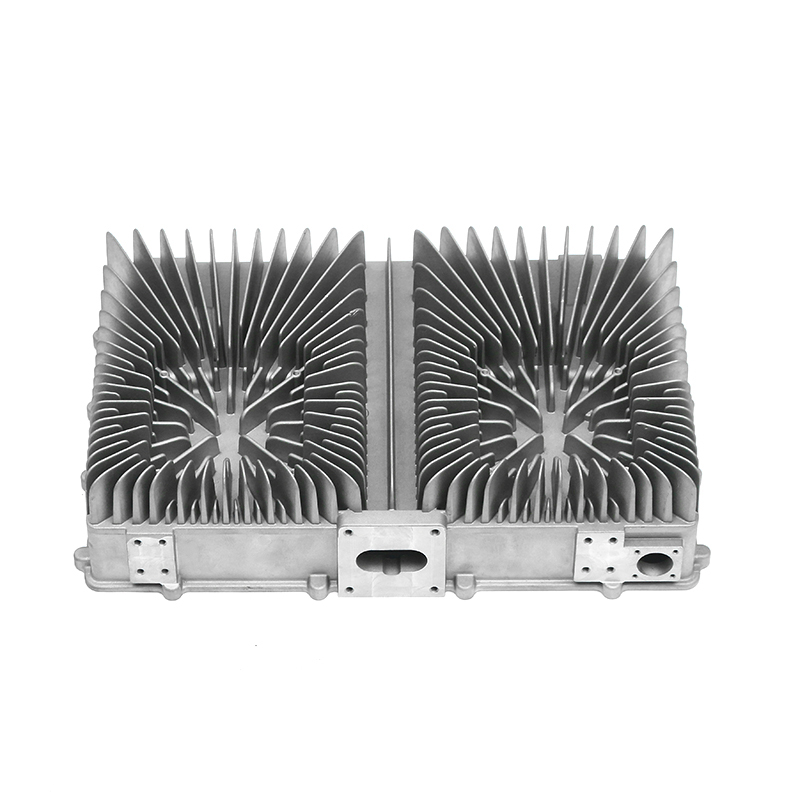

During the operation of the gearbox, the internal gears and bearings will produce continuous friction and impact. If the surface hardness of the housing is insufficient, long-term wear will cause the gearbox performance to decline or even fail.

Nano coating materials usually have ultra-high hardness and excellent wear resistance, which can effectively improve the wear resistance of the gearbox housing surface. This surface coating can reduce the damage to the housing caused by mechanical friction, and can also reduce the energy loss caused by wear, thereby improving the vehicle's transmission efficiency and fuel economy.

Another notable feature of nano coating technology is its self-cleaning ability. The surface of this coating has hydrophobic and oleophobic properties, which can effectively prevent dirt, oil and other pollutants from adhering to the gearbox housing.

For vehicles, self-cleaning performance can reduce the accumulation of dirt on the surface of the gearbox housing, thereby reducing the difficulty of cleaning and maintenance, especially in long-distance driving or bad road conditions. This performance is particularly important. The anti-fouling performance of the surface can also prevent pollutants from entering the internal transmission system, further ensuring the normal operation of the gearbox.

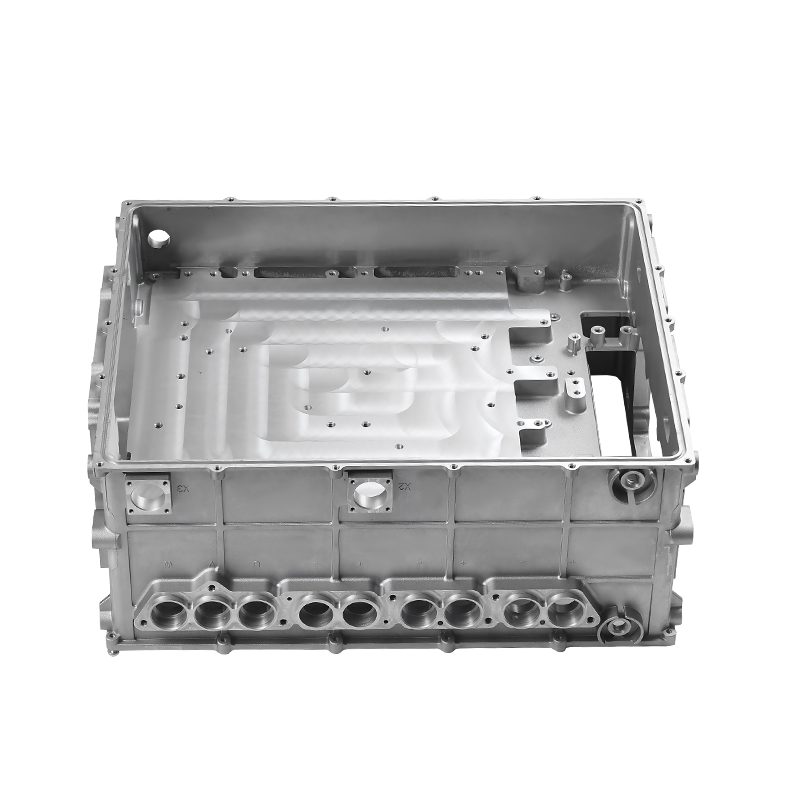

With the general trend of the automotive industry pursuing lightweight, lightweight material selection and surface treatment technology have become important considerations.

Compared with traditional thick coating technology, the thickness of nano coating is usually at the micron level or even thinner, which hardly increases the weight of the gearbox housing, thus meeting the needs of automakers for lightweight. In addition, the thin coating can also ensure the accuracy and dimensional stability of the gearbox housing without affecting the assembly and transmission performance of internal components.

With the increasing popularity of new energy vehicles and smart cars, the technological upgrade of the powertrain has become an inevitable trend. The introduction of nano-coating technology provides new possibilities for improving the performance of key components such as Gearbox Housing. In the future, this technology will be more widely used.

Nano-coating technology does not require the use of harmful chemicals, which meets the increasingly stringent environmental protection requirements of the automotive industry. At the same time, the recyclability of coating materials also provides the possibility for green manufacturing of automotive parts.

The development of digital manufacturing technology also allows nano-coating technology to be combined with smart sensors and self-healing materials to achieve a more intelligent surface treatment process. For example, self-healing nano-coatings can automatically repair themselves when the surface is damaged, thereby extending the service life of the gearbox housing.

The future nano-coating process will be more efficient and precise, and automated equipment and robotics will achieve large-scale, low-cost surface treatment, further improving the manufacturing efficiency of the gearbox housing.