The automobile engine is a high-temperature, high-pressure, and high-load system with a complex internal environment and long-term challenges from the external environment. As an important protection system for the engine, the filter element is responsible for filtering impurities in the air, oil, and fuel entering the engine system to ensure that the engine operates in a clean environment. The filter element holder must not only ensure the stability and effective support of the filter element, but also deal with the high temperature and vibration generated when the engine is running, as well as the erosion of moisture, salt, and acidic substances in the external environment. If the corrosion resistance of the filter element holder is insufficient, long-term exposure to these harsh environments will cause oxidation and corrosion on the surface of the holder, which will affect the fixing effect of the filter element and even cause the filter element to fail, affecting the performance of the engine and shortening the service life of the vehicle. The impact of corrosion on the filter element holder is not limited to the physical level, but may also cause the filter element to loosen and dislocate, so that the engine cannot be effectively protected and increase the risk of failure. Therefore, the corrosion resistance of the filter element holder is crucial to ensure the long-term stable operation of the car.

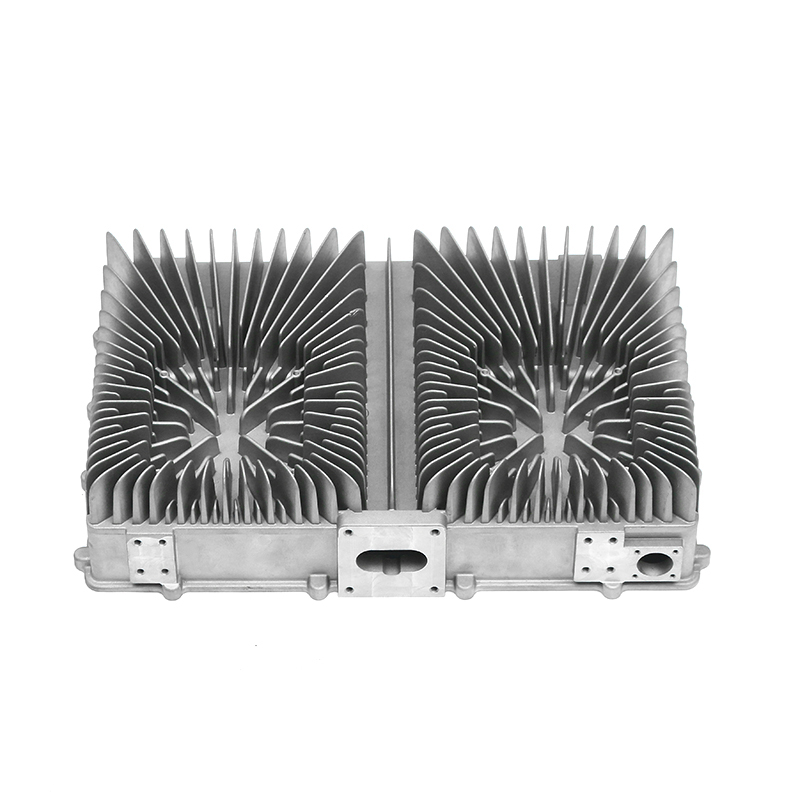

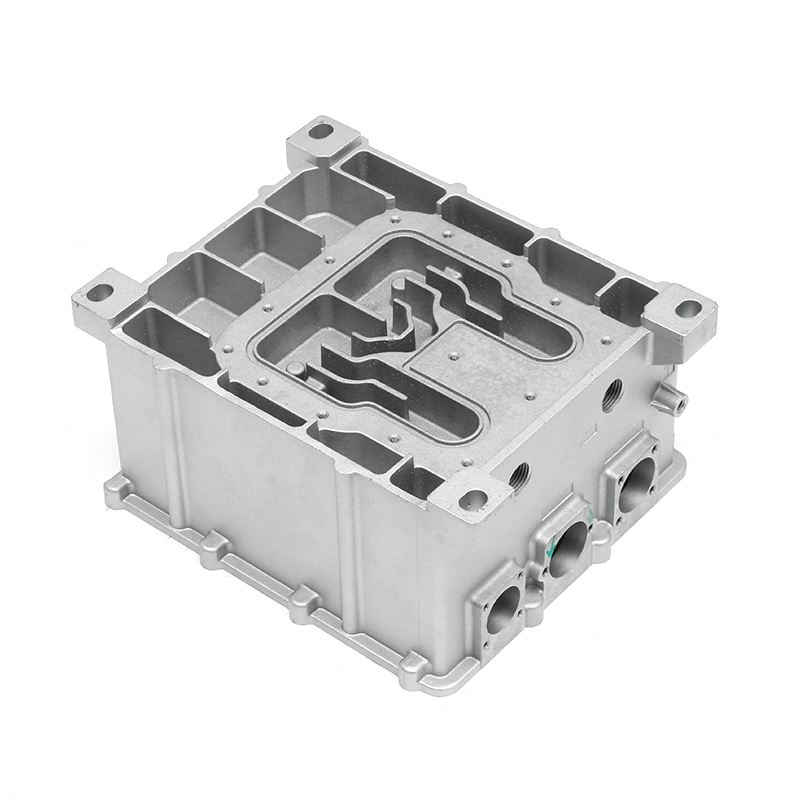

The design of the Car Filter Holder must fully consider the harshness of its use environment. In order to ensure that the filter element can still operate stably in high temperature, high humidity and corrosive environment, the filter element bracket is usually made of high-quality metal materials with strong corrosion resistance, such as aluminum alloy, stainless steel, etc. These materials have excellent anti-oxidation and anti-corrosion capabilities. Compared with traditional steel, these highly corrosion-resistant materials can effectively resist chemical corrosion such as moisture, salt, acidic substances in the air, and extend the service life of the filter element bracket.

In terms of material selection, Car Filter Holder usually undergoes surface treatment, such as anodizing, electroplating or spraying, to further enhance the corrosion resistance of the bracket. Through these treatment processes, a protective film will be formed on the surface of the filter element bracket, which can effectively resist corrosive substances in the external environment and maintain the strength and stability of the filter element bracket. This reduces the maintenance and replacement costs caused by corrosion and improves the long-term stability of the vehicle.

The corrosion resistance of the filter element bracket directly determines its ability to work stably in harsh environments, which in turn affects the stability and performance of the filter element. If the Car Filter Holder can effectively prevent corrosion, it can avoid deformation, failure or loosening of the filter element bracket due to material aging, oxidation, corrosion and other reasons, thereby ensuring that the filter element is always in a fixed and stable working state. The working performance of the filter element depends on the stability of the bracket. Once the bracket is corroded, it may cause the filter element to deviate, affecting its filtering effect, and even oil and air leakage may occur. In severe cases, it may also cause engine failure.

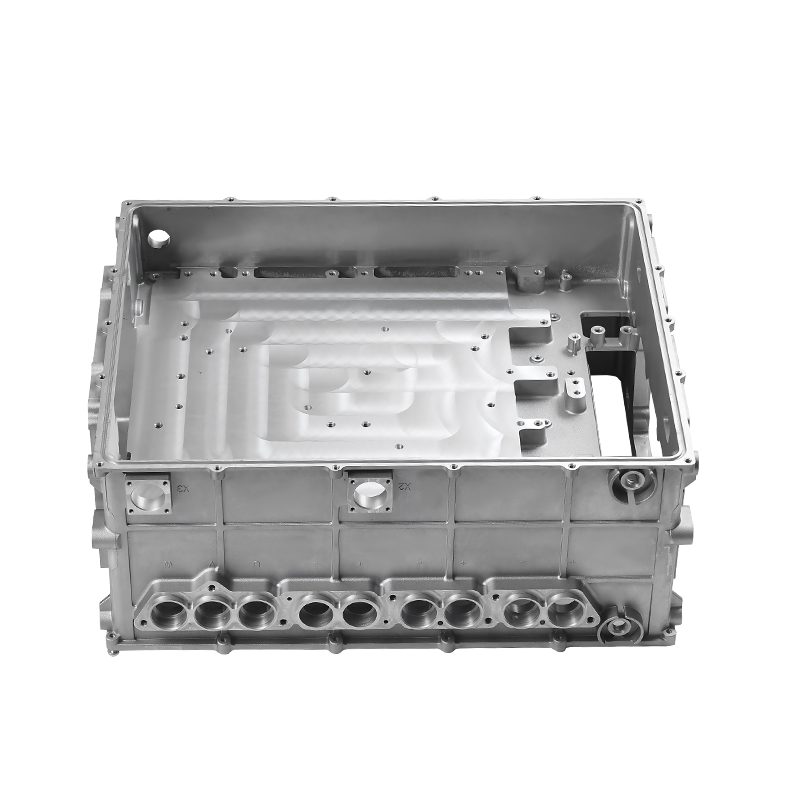

Improving corrosion resistance allows the Car Filter Holder to protect the filter element from corrosion, and also ensures that the engine system can work in a clean and stable environment, avoiding pollutants from entering the engine, causing wear, damage and pollution of internal and external components. During long-term use, the life of the engine can be extended and the performance can be fully utilized.

During long-term driving, especially in harsh weather conditions, the working environment of the car engine is very complex. Car owners usually drive in different climates and road conditions, and the engine will experience the influence of various factors such as high temperature, low temperature, rain, and salt spray. In this case, the corrosion resistance of the Car Filter Holder is particularly important. It can effectively prevent erosion from the outside world and maintain the strength and stability of the filter holder, thereby ensuring that the entire engine filtration system can continue to operate effectively.

With the increasing popularity of new energy vehicles and traditional fuel vehicles, automakers have higher and higher requirements for the durability and reliability of various components. In particular, the battery system and power management system of new energy vehicles need to maintain stable working performance for a long time, which makes the requirements for the filter system more stringent. The corrosion resistance of the Car Filter Holder not only ensures the normal operation of the filter element, but also further improves the stability of the entire vehicle system, avoids system failures caused by corrosion, and thus improves the overall durability and reliability of the vehicle.