The design of new energy motor housing plays a crucial role in influencing the overall efficiency and performance of new energy motors in several ways.

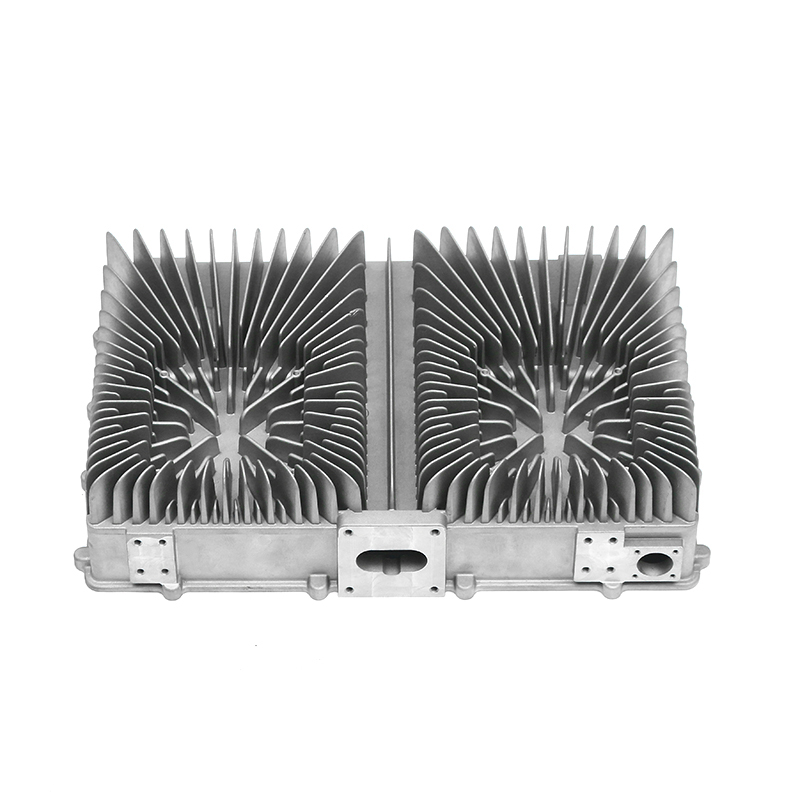

Thermal Management: Effective heat dissipation is essential for maintaining optimal operating temperatures. The housing design can incorporate features like cooling fins, ventilation openings, or heat sinks to enhance airflow and reduce overheating, which in turn improves efficiency and extends motor life.

Weight Reduction: Lightweight materials and streamlined designs help reduce the overall weight of the motor. A lighter motor can improve efficiency, especially in applications like electric vehicles, where reducing weight contributes to better energy consumption and performance.

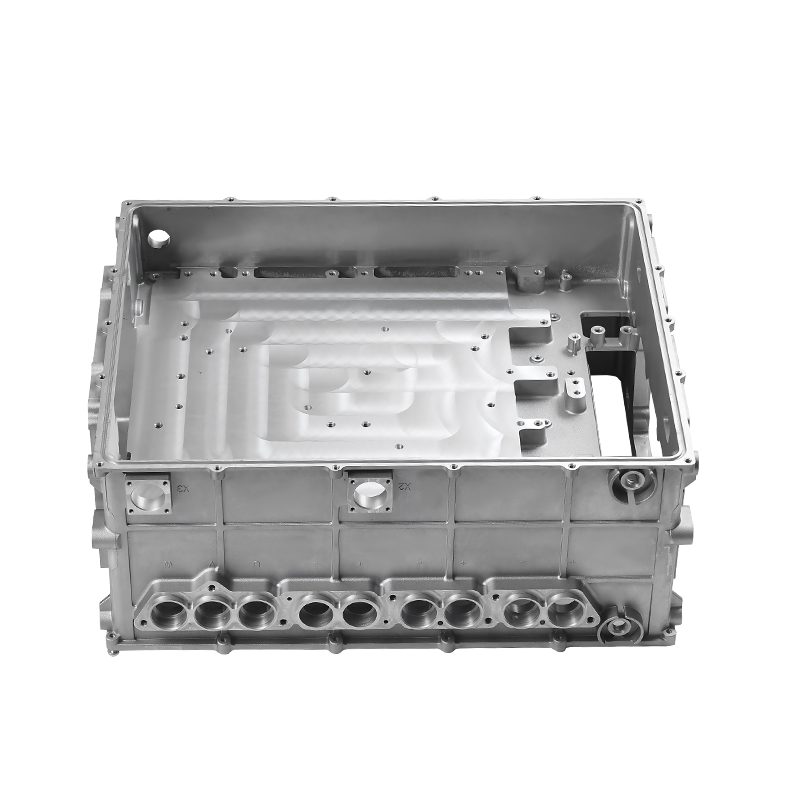

Structural Integrity: A robust housing design provides the necessary support for internal components, ensuring alignment and stability. This structural integrity minimizes vibrations and mechanical stress, which can adversely affect performance and lead to wear over time.

Noise and Vibration Dampening: An optimized housing design can help mitigate noise and vibrations during operation. This is not only important for user comfort but also enhances the motor's efficiency by reducing energy loss associated with vibration.

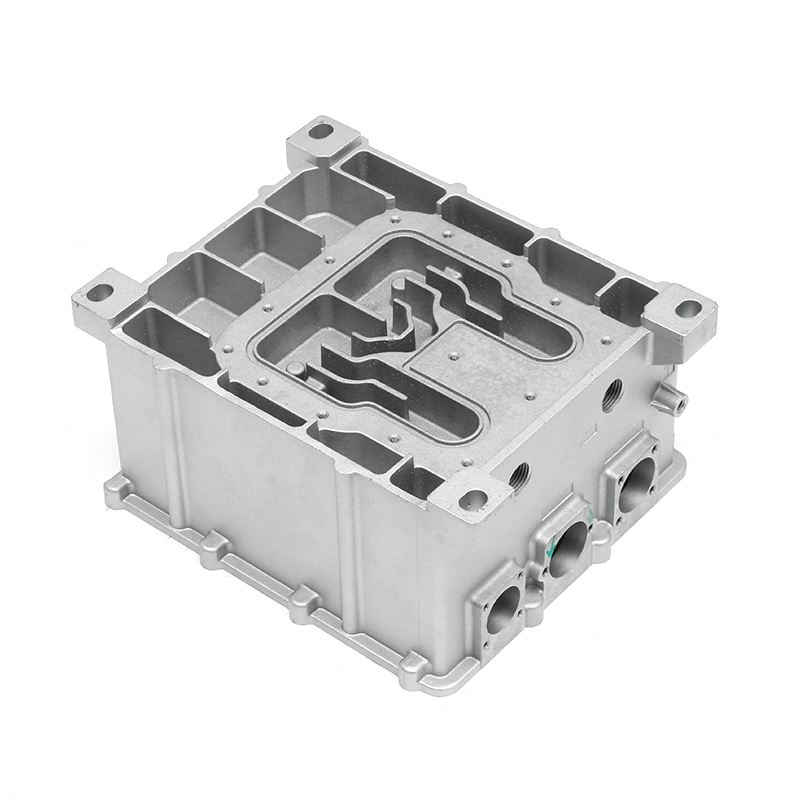

Sealing and Protection: Proper sealing in the housing prevents dust, moisture, and other contaminants from entering the motor. This protection is crucial for maintaining performance and longevity, particularly in harsh environments, as contaminants can lead to increased friction and inefficiencies.

Integration of Cooling Systems: Housing designs that facilitate the integration of advanced cooling technologies (such as liquid cooling systems) can significantly improve performance. These systems help manage heat more effectively than traditional air cooling methods.

Electromagnetic Compatibility: The housing can influence electromagnetic interference (EMI) and compatibility (EMC). A well-designed housing can shield sensitive components from EMI, ensuring stable operation and enhanced performance.

Modular Design: A modular housing design allows for easier upgrades and repairs, which can lead to improved performance over the motor's lifecycle. It also enables the integration of advanced technologies as they become available.

Manufacturing Precision: The precision with which the housing is manufactured affects the fit and function of internal components. Tighter tolerances can lead to better efficiency by minimizing gaps and misalignments that could cause energy loss.

Recommended Products

Products provided by famous enterprises are deeply trusted by users.