1. Precise temperature control, personalized comfort experience

The new energy electronically controlled air cooling system, with its advanced electronic control technology, can achieve subtle control of indoor temperature, far beyond the single temperature setting mode of traditional air conditioners. The system's built-in intelligent sensor can monitor indoor temperature, humidity, human activity and other parameters in real time, and automatically adjust to the temperature that best suits the current environment and human perception through complex algorithm analysis. This personalized temperature control strategy not only avoids the discomfort caused by excessive temperature difference, but also effectively prevents health problems that may be caused by being in a fixed temperature environment for a long time, such as "air conditioning disease". In addition, users can also remotely control the temperature at home anytime and anywhere through mobile phone APP, enjoying the ultimate convenience and comfort.

2. High efficiency and energy saving, reducing energy consumption costs

The high efficiency and energy consumption characteristics of the new energy vehicle electronic control system and air cooling system provide a powerful reference for the application of new energy electronic temperature controlled air cooling system in the home field. The system adopts advanced frequency conversion technology and energy efficiency optimization algorithm, which can automatically adjust the operating speed of the compressor and fan according to the indoor load to avoid unnecessary energy waste. During the cooling or heating process, the system can accurately control the input and output of energy to ensure that every bit of energy can be fully utilized. This energy-efficient design not only reduces household energy expenses, but also reduces the impact on the environment, which is in line with modern families' pursuit of green and low-carbon life.

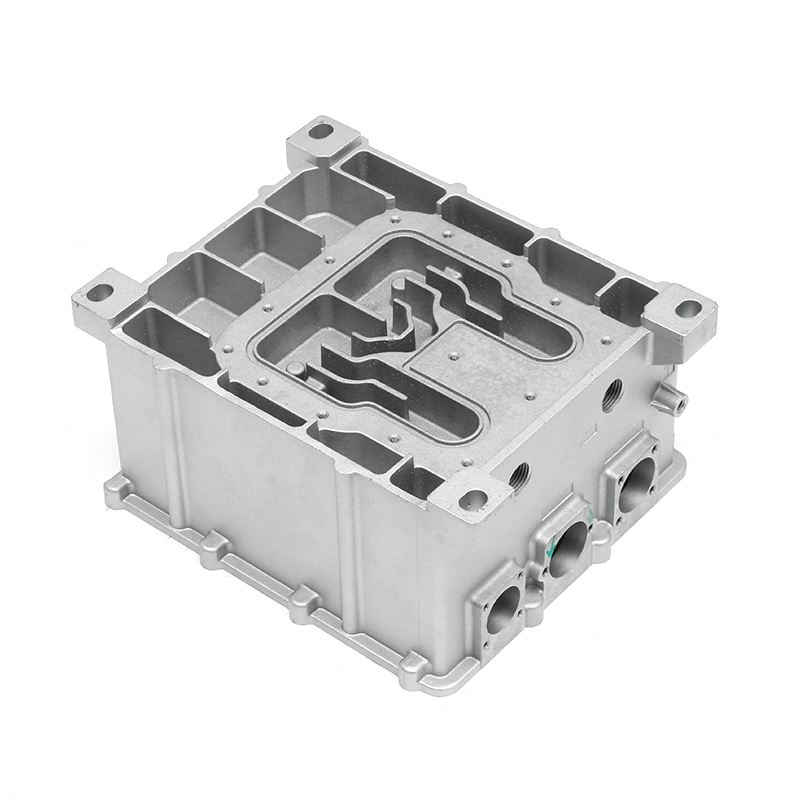

3. Customized molds to meet diverse needs

The high customization requirements of the electric control air cooling system of new energy vehicles have promoted the continuous advancement of mold manufacturing technology. Similarly, the application of new energy electric control air cooling series molds in the home field also shows strong customization capabilities. Mold manufacturers can tailor suitable air cooling system molds according to the specific needs of customers and the actual conditions of the home environment. Whether it is wall-mounted, cabinet-type or embedded installation, whether it is simple style, retro style or modern technology-filled appearance design, it can be met. This highly customized service not only enhances the overall beauty and personalization of the home, but also ensures the perfect integration of the air cooling system and the home environment.

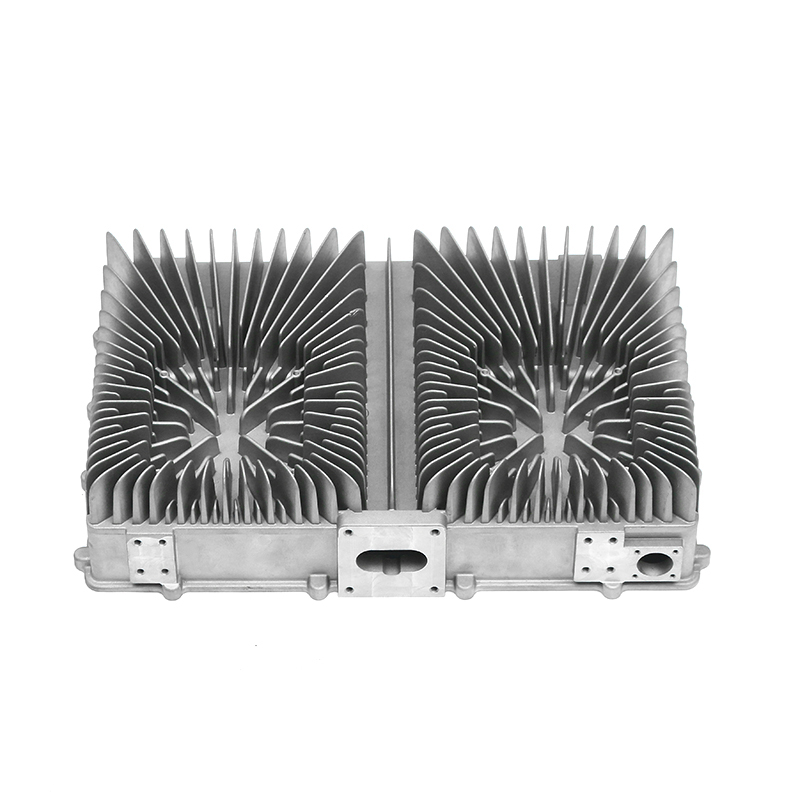

4. Precision processing to ensure stable quality

In the design and processing process of the new energy electric control air cooling series molds, the most advanced CAD/CAM technology and high-precision processing equipment are used. The application of these high-tech means makes the mold manufacturing process more precise and efficient. Through 3D modeling and simulation, designers can complete the preliminary design and optimization adjustment of the mold on the computer, avoiding the errors and defects that may exist in traditional manual design. At the same time, high-precision processing equipment can ensure that each component of the mold achieves extremely high dimensional accuracy and surface quality, providing a solid foundation for subsequent molding processes such as injection molding or die casting. The application of this precision processing technology not only improves the quality stability of the mold, but also ensures that the air cooling system can maintain excellent performance during use.

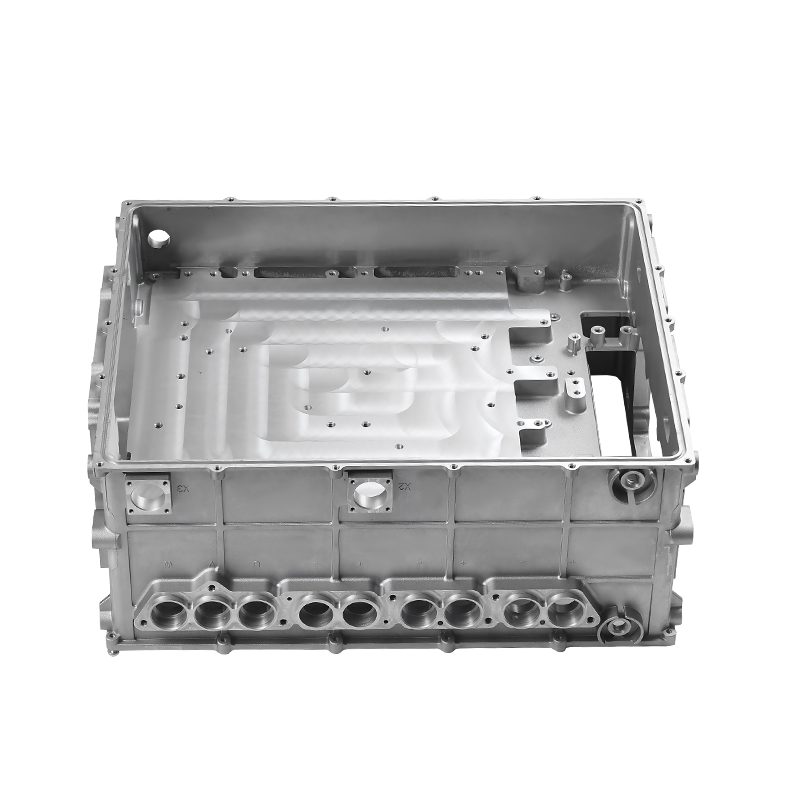

5. Durable and stable, extending service life

The new energy electric control air cooling series molds have also made great efforts in material selection and process application. The mold manufacturer selected high-quality steel, alloy and other wear-resistant, high temperature resistant and corrosion-resistant materials as the main components of the mold. These materials not only have good mechanical properties and processing properties, but also can maintain stable physical and chemical properties during long-term use. In addition, advanced heat treatment, surface treatment and other process methods are also used in the mold processing process to further improve the hardness and wear resistance of the mold. The combined effect of these measures enables the new energy electric control air cooling series molds to resist the test of various harsh environments and complex working conditions during use, maintaining stable performance output and a long service life. This not only reduces the frequency and cost of mold replacement, but also provides users with a more reliable and durable air cooling system product.