The cooling system of new energy vehicles faces many challenges, one of which is how to ensure stable operation in extreme environments. Since the core components of electric vehicles such as batteries and motors generate a lot of heat during operation, the cooling system must withstand environmental factors such as high temperature, low temperature, and high humidity during operation. Therefore, the reliability of the cooling system is related to the working efficiency of the system itself, and also directly affects the safety and service life of the entire vehicle.

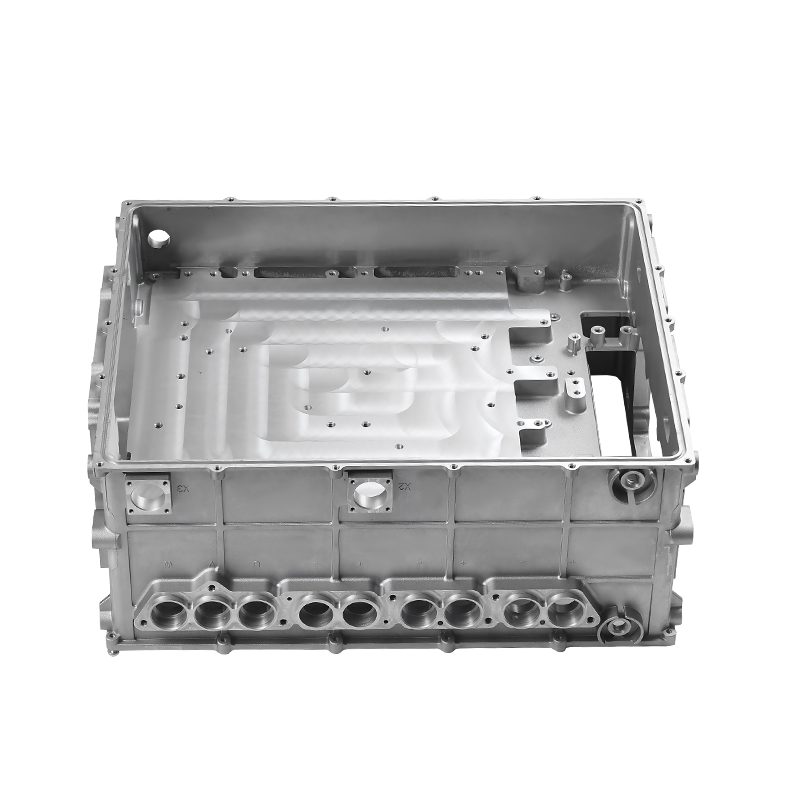

The design of the New Energy Electronically Controlled Water Cooling Series fully considers these challenges and adopts high-reliability technology that has been precisely designed and verified. All key components of this series of products, such as water pumps, radiators, water tanks, etc., are made of strictly screened high-quality materials to ensure that they can still maintain excellent performance under long-term high-load operation.

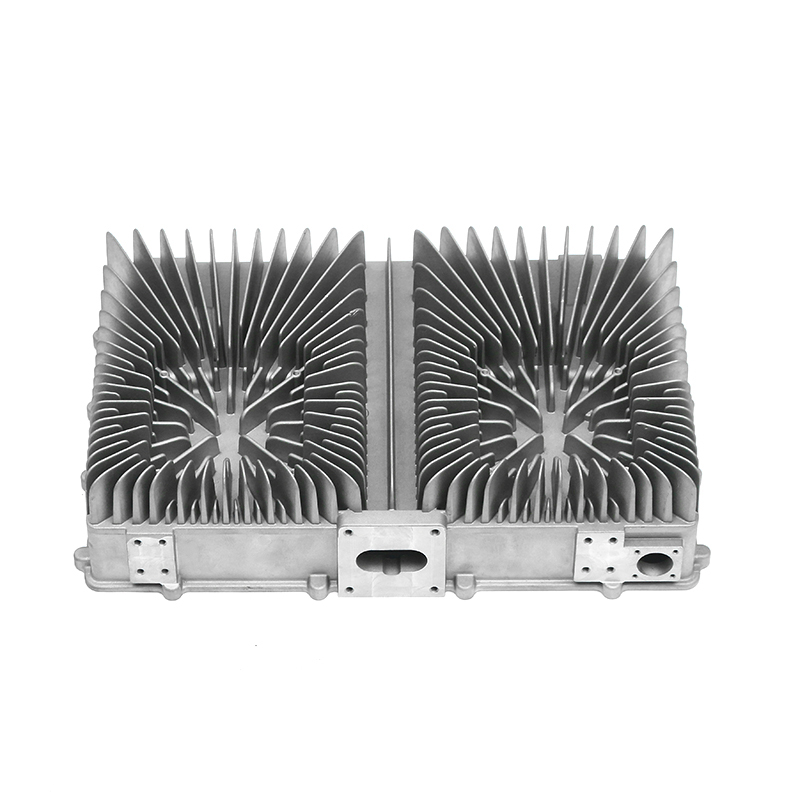

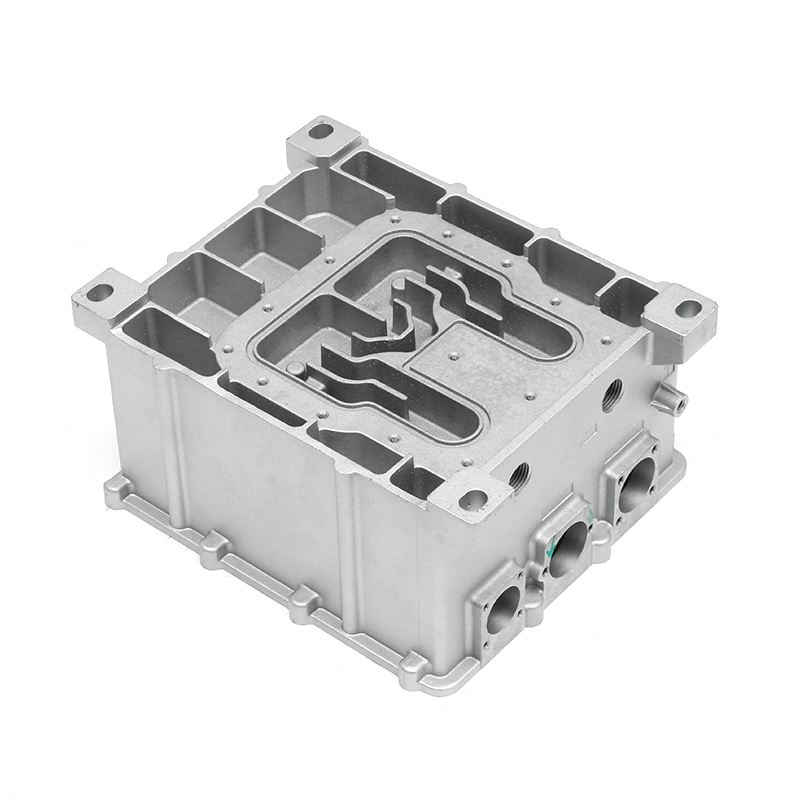

During the manufacturing process, Ningbo Fenda relies on its rich experience in mold manufacturing to ensure that each set of New Energy Electronically Controlled Water Cooling Series has undergone high-precision processing and strict quality control. The precise mold manufacturing process ensures the dimensional accuracy and matching accuracy of each component of the water cooling system, thereby effectively avoiding problems such as water leakage and reduced heat dissipation efficiency caused by loose components or dimensional errors.

For electric vehicles, the water cooling system needs to work stably in a wide range of ambient temperatures, especially in some extreme environments, such as driving conditions in high temperature, high humidity or low temperature areas. Traditional water cooling systems often face problems such as poor sealing, material aging, and heat dissipation effect decline in these environments, which will affect the overall performance and safety of electric vehicles.

The high reliability design of the Xinneng Electronic Control Water Cooling Series is optimized for these extreme environmental conditions. The core components of this series of products, such as the radiator and water pump, use advanced high temperature resistant and corrosion resistant materials, and have been tested and verified many times to ensure that they can quickly and effectively dissipate heat in high temperature environments, and quickly start in low temperature environments, ensuring that components such as batteries and motors of electric vehicles are always maintained within a reasonable temperature range.

In areas with high humidity or rainy and snowy weather, the corrosion-resistant design of the Xinneng Electronic Control Water Cooling Series can also ensure the long-term stability of the system. The sealing of the water cooling system has been comprehensively improved, effectively preventing water infiltration and component corrosion, thereby extending the service life of the entire cooling system and ensuring that electric vehicles can still maintain efficient and stable performance in extreme environments.

One of the keys to ensuring the high reliability and stability of the cooling system lies in the selection of materials and the control of the manufacturing process. Ningbo Fenda New Energy Technology Co., Ltd. pays special attention to the selection of materials and the refinement of processes in the design and manufacturing process of the new energy electronic control water cooling series. All key components are made of high-strength, high-temperature resistant and corrosion-resistant materials, which can maintain the stability of their physical properties under high pressure, high temperature or harsh environmental conditions.

Ningbo Fenda uses advanced CNC processing equipment and precision friction stir welding technology to ensure the processing accuracy of each component of the product. Through strict quality control processes, the company ensures that each water cooling system meets high standards and avoids any unstable factors in actual use.

Throughout the production process, every link of the New Energy Electronically Controlled Water Cooling Series has been strictly tested and verified. Before leaving the factory, the product needs to pass a number of rigorous tests such as high temperature, high pressure, low temperature, and corrosion resistance to ensure that it can cope with the actual use needs under different environmental conditions.

The rapid development of new energy vehicles has higher and higher requirements for the cooling system, especially in the context of the gradual increase in battery and motor power. The stability and efficiency of the cooling system have become key factors. Ningbo Fenda New Energy Technology Co., Ltd. has always been committed to continuous innovation and optimization of technology, and continuously improving the performance and reliability of products to meet the needs of the future new energy vehicle industry. The design concept of the new energy electronic control water cooling series meets the needs of the current market and lays the foundation for future technological progress. Through close cooperation with customers, Ningbo Fenda fully considers the trends of the new energy vehicle industry during the research and development process, and continuously improves the design of the cooling system to enable it to cope with higher power output and more complex working environments.